Here at Advanced Filtration, we work with all kinds of industrial filtration parts and equipment in all kinds of industries. One particular type of equipment that we come across is the butterfly valve, which is a quarter-turn valve regulating fluid flow through a pipe.

If you’re looking into butterfly valves and need to know more, look no further. Or go directly to our product page for our Islip Flow Controls (IFC) Butterfly Valves.

How Does a Butterfly Valve Work?

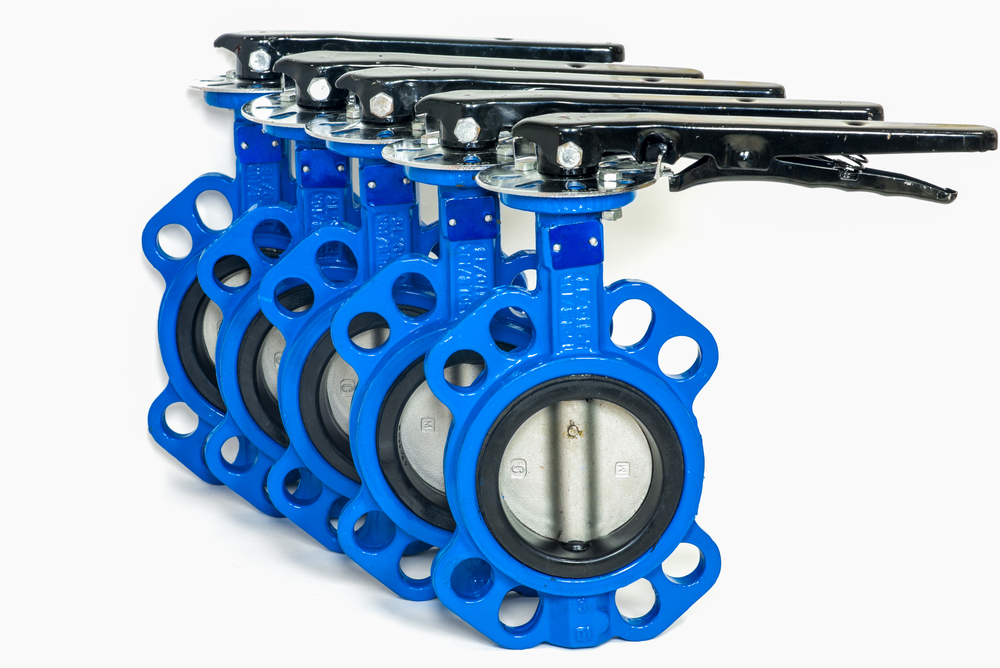

A butterfly valve is a type of quarter-turn valve that regulates the flow of fluid through a pipe. The valve consists of a disc or a plate that is mounted on a shaft. The plate is positioned in the center of the pipe and rotates around the shaft to control the flow of fluid.

When the valve is fully open, the plate is positioned parallel to the pipe, allowing the fluid to flow freely. When the valve is closed, the plate is turned perpendicular to the pipe, blocking the flow of fluid.

The butterfly valve is operated by turning a lever or a handwheel, which rotates the shaft and plate. The valve can be adjusted to allow for precise control of the flow of fluid. The valve can also be used to completely shut off the flow of fluid in the pipe.

Butterfly valves are commonly used in industries that require the regulation of fluid flow, such as chemical, pharmaceutical, and water treatment plants. They are preferred over other types of valves because they are easy to install, require minimal maintenance, and are cost-effective.

Why Is a Butterfly Valve So Important in Industrial Filtration?

A butterfly valve is important because it is a simple and efficient way to regulate the flow of fluid in a pipeline. It provides a quick quarter-turn operation, which makes it easy to operate and control the flow of fluid. Additionally, butterfly valves have a low-pressure drop across the valve, which means that they don’t cause significant resistance to the flow of fluid. This makes them a preferred choice for applications where the flow of fluid needs to be regulated without causing excessive pressure drop.

Butterfly valves are also compact and lightweight, which makes them easy to install and maintain. They are often used in industries such as chemical, pharmaceutical, and water treatment, where they can be used to control the flow of various fluids, including corrosive or abrasive materials.

Overall, butterfly valves are an important component of many fluid handling systems because they provide reliable, efficient, and cost-effective control of fluid flow.

How Are Butterfly Valves Used in Different Applications?

Butterfly valves have a wide range of applications in different industries due to their versatility, efficiency, and cost-effectiveness. Some of the common applications of butterfly valves include:

- Water and wastewater treatment: Butterfly valves are used to regulate the flow of water and wastewater in treatment plants, including water intake and discharge lines, as well as in the treatment processes.

- HVAC systems: Butterfly valves are commonly used in heating, ventilation, and air conditioning systems to regulate the flow of air, water, or steam in pipes.

- Chemical and petrochemical industries: Butterfly valves are used in the handling of chemicals, gases, and fluids in various processes such as mixing, blending, and transferring.

- Food and beverage industries: Butterfly valves are used in the food and beverage industry for applications such as regulating the flow of liquids in processing and packaging systems.

- Power generation: Butterfly valves are used in power plants for controlling the flow of steam, condensate, and cooling water.

- Marine and offshore applications: Butterfly valves are used in the marine industry for regulating the flow of seawater, fuel, and other fluids.

- Fire protection systems: Butterfly valves are used in fire protection systems to control the flow of water and fire suppression agents.

Overall, butterfly valves are versatile and widely used in various industries for regulating the flow of fluids, gases, and other media.

Is There A Difference Between Butterfly Valves and Ball Valves?

Butterfly valves and ball valves (which we also carry) are both used to regulate the flow of fluid in a pipeline, but they operate differently and have different design characteristics. Here are some of the main differences between the two types of valves:

- Design: A butterfly valve consists of a circular disc that rotates around a central axis to control the flow of fluid, while a ball valve consists of a spherical ball with a hole in the middle that rotates within a socket to regulate the flow of fluid.

- Flow control: Butterfly valves are better suited for regulating the flow of fluid, while ball valves are designed for on/off control. Butterfly valves can be used for throttling applications, while ball valves are used for isolation applications.

- Pressure drop: Butterfly valves typically have a lower pressure drop than ball valves, meaning they cause less resistance to fluid flow. This makes them a better choice for applications where pressure loss is a concern.

- Size and weight: Butterfly valves are typically smaller and lighter than ball valves, which makes them easier to install and operate in space-restricted areas.

- Cost: Butterfly valves are generally less expensive than ball valves, making them a cost-effective choice for many applications.

Overall, both butterfly valves and ball valves have their own advantages and disadvantages, and the choice between them depends on the specific application requirements, such as the type of fluid, pressure and temperature conditions, flow rate, and valve size.

Look to Advanced Filtration for Your Butterfly Valve Needs

We carry a wide range of filtration products, including butterfly valves. If you’re not sure exactly what you need, give us a call at 732-901-6676, or fill out our contact form for a free consultation. We’ll get you sorted.