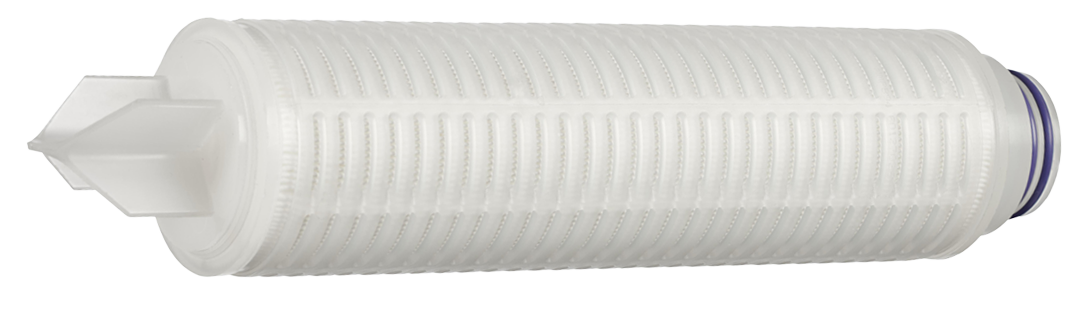

Here at Advanced Filtration, we deal with tons of different kinds of industrial filters, for all manner of applications–from power generation to manufacturing to pharma and biotech. Similarly, the filters we sell comes in all shapes and sizes–and are made from different materials. In this article, we’re going to look at what kinds of materials go into different industrial filters, and what they are used for.

What Are Industrial Filters Made From?

Industrial filters can be made from various materials depending on their application and requirements. Here are some common materials used in the manufacturing of industrial filters:

- Metal: Metal filters are made from materials such as stainless steel, aluminum, or copper. They are commonly used in applications where high-temperature resistance, durability, and robustness are required. Metal filters can be reusable and are often used in industries such as oil and gas, chemical processing, and automotive manufacturing.

- Synthetic Fibers: Synthetic fibers like polyester, polypropylene, and nylon are widely used in filter production. These fibers offer excellent chemical resistance, durability, and high dirt-holding capacity.

- Cellulose: Cellulose fibers, derived from wood pulp, are commonly used in filters. They are cost-effective and provide good filtration efficiency for many applications. Cellulose filters are often used for general filtration purposes.

- Ceramic: Ceramic filters are made from porous ceramic materials. They offer excellent thermal stability, chemical resistance, and high filtration efficiency. Ceramic filters are commonly used in applications where high-temperature filtration or specialized chemical filtration is required, such as in the pharmaceutical and chemical industries.

- Glass Fiber: Glass fiber filters are made from fine glass fibers. They offer high filtration efficiency, chemical resistance, and dimensional stability. Glass fiber filters are commonly used in applications where fine particulate filtration or air filtration is required, such as in cleanrooms, HVAC systems, and laboratory settings.

- Activated Carbon: Activated carbon filters are made from activated carbon, which is derived from materials like coconut shells, coal, or wood. Activated carbon has a high adsorption capacity, making it effective for removing odors, gases, and certain contaminants from air or liquids. These filters are commonly used in air purifiers, water treatment systems, and industrial processes.

It’s important to note that the specific choice of filter material depends on the intended application, desired filtration efficiency, operating conditions, and other factors. Different combinations or layers of materials may be used to achieve specific filtration requirements.

Contact Advanced Filtration For All Your Industrial Filtration Needs

Regardless of what your filter is made from, or what type of application it’s being used for, Advanced Filtration can provide it–or we can help you find what you’re looking for. Give us a call at 732-901-6676 or contact us here for a free consultation.