We at Advanced Filtration have been working with industrial filters for decades, and it comes pretty naturally to us by now. But we appreciate that for people who are new to the business, filtration can be a complicated topic, and it can be frustrating to find simple answers to your questions about duplex strainers. To help simplify matters for both our customers and for people in the field who are looking for more information, we’ve written this quick guide to what you need to know about duplex strainers, starting with the most basic question: what is a duplex strainer?

- Duplex strainers are filters – A filter is any device which removes impurities from a substance that passes through it. One type of filter is a “strainer,” which physically blocks unwanted substances from moving through a pipeline system, and one type of strainer is a duplex strainer, which can be used to remove contaminants or to control the size of particles.

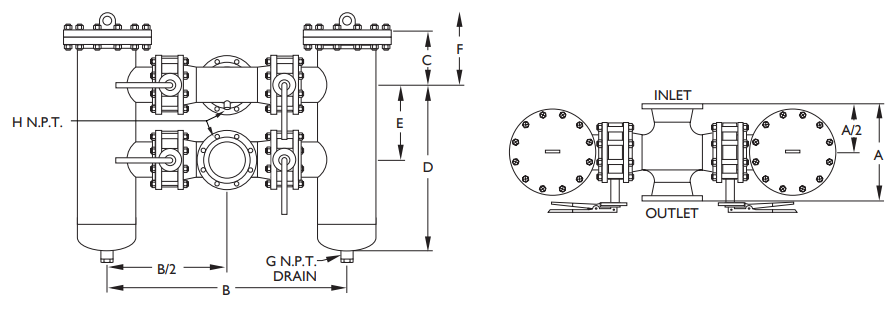

- Operation is straightforward – Although there are many types of duplex strainer, the general principle is straightforward. There are two baskets, and each performs the function of an ordinary simplex strainer: removing impurities, particles, or debris from the substance passing through a pipeline system. Valves connect the baskets to each other and to the pipeline system, and operating these valves controls the flow to one or both of the baskets.

- Maintenance isn’t difficult – In most applications, both baskets will be open for normal operation, but the pipeline system can function adequately with only one. While one basket is closed, the other can be cleaned, repaired, or maintained. This may be done manually, but many duplex strainers may even perform these functions automatically.

- Duplex strainers operate continuously – The key distinction between duplex strainers and other types of strainer is that cleaning duplex strainers does not require the pipeline system to be stopped. They are essential for continuous flow processes because the process is not interrupted by maintenance of the duplex strainer.

- Duplex strainers have many uses including a wide range of applications, mostly industrial. As an integrated part of a pipeline system. They can be used with water, oil, fuel, or other liquids. They are used in the processing of chemicals, food, fuel, pharmaceuticals, minerals and mining, paper, water, minerals, sewage and waste management, and a variety of other areas.

- Duplex strainers are diverse – Given the tremendous number of industries that rely on strainers, it’s no surprise that there are as many different ones as there are applications. Some are primarily intended to remove unwanted or dangerous particles from a substance that will reach consumers directly, while others simply remove particles that are hazardous to the operation of the pipeline system itself. Even though they may function in the same way, they may have very different appearances based on their materials, conditions, and safe usage limits.

- Duplex strainers are part of our lives – Throughout the average day, you may encounter many things that rely on them. A glass of juice with breakfast? That juice was probably squeezed through a duplex strainer. Reading the morning newspaper? The pulp for the paper and the ink for the presses went through one. Taking a shower? Wastewater passes through one in your local sewage system. Drive to work? The fuel you use probably passed through many on its journey from crude oil to your car. They are everywhere!

We hope this short introduction to duplex strainers has been helpful for non-specialists, and don’t hesitate to contact Advanced Filtration at 732-901-6676 for expertise and answers regarding your specific needs.