The Power of Fabricated Strainers in Industry

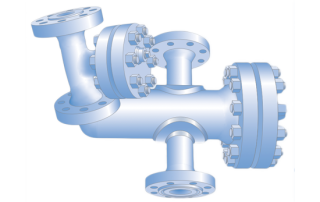

Here at Advanced Filtration, we constantly work with complex mechanical components that play an integral role in managing and maintaining processes. One such component that holds significant importance is fabricated [...]