Triple Duty Valves: What You Need To Know

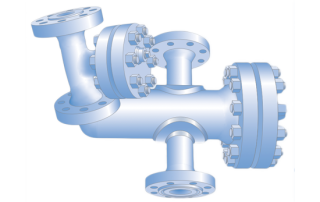

Advanced Filtration deals with various industries where fluid handling is essential, and the efficient regulation and management of flow rates, pressure, and temperature are paramount. One crucial component that aids [...]