From extending equipment lifespan to enhancing oil quality, a reservoir desiccant breather, or desiccant filter breather, offers many benefits in a variety of industrial filtration application. They are integral in maintaining production levels and durability within critical systems—casting a ripple effect that stretches from improved operations to substantial savings in costs.

But what exactly is a reservoir desiccant breather? And why is it essential for your system? In this article, the industrial filter experts at Advanced Filtration in New Jersey will answer these questions, and more.

What Is A Reservoir Desiccant Breather?

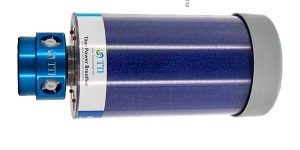

A reservoir desiccant breather, commonly known as a ‘desiccant filter breather’ or ‘breather desiccant,’ is indeed designed to safeguard enclosed systems, particularly reservoirs, from moisture and particulate contamination. These contaminants typically enter through air vents during the operational inhale-exhale process of the system. The purpose is to maintain the integrity of the fluid within the system by preventing the intrusion of external elements that could compromise its purity.

This technology is frequently utilized in hydraulic systems, where the purity of the fluids is of utmost importance. The breather acts as a gatekeeper, allowing the desired airflow while effectively blocking unwanted particles and moisture from entering the reservoir. This helps in preserving the quality and functionality of the fluid within the hydraulic system.

Why Are Reservoir Desiccant Breathers Important In Industrial Filtration?

Breathers in a reservoir system serve several valuable purposes:

- Preventing Microbial Growth and Contamination: Breathers help maintain optimal internal conditions within the reservoir, inhibiting microbial growth that could otherwise deteriorate the fluid, corrode interior walls, or block conduits over time. This action helps to preserve the quality of the fluid and the infrastructure of the system.

- Extending Lifespan of Fluids and Machinery Components: Using different types of breathers based on specific needs ensures a longer lifespan for both the fluids and the expensive components of machinery. This action reduces the likelihood of degradation, thereby minimizing the need for premature maintenance or replacements.

- Mitigating the Risk of Component Failure: By preventing airborne pollutants from entering the system, breathers help to reduce the risk of premature component failure. This, in turn, can decrease unforeseen downtime and costly repair expenses, providing significant cost savings in the long run.

- Shielding Against Moisture: Breathers act as a defense against moisture by absorbing water vapor before it can affect the hydraulic fluid or cause breakdowns. This ensures that lubricants function at their best and machine components remain operational, optimal, and resilient even in challenging conditions.

In summary, there are many benefits that breathers offer in a reservoir system, such as preserving fluid quality, extending machinery life, reducing the risk of failures, and protecting against moisture-related issues.

How Does A Desiccant Filter Breathers Work?

Desiccant filter breathers are a key component within reservoir desiccant breathers. They consist of a network designed to trap moisture and particulates from the air that enters the system.

Desiccants, such as silica gel, are materials with a natural affinity for water molecules and have the ability to attract and retain them from the surrounding environment. When air passes through the desiccant filter breather, the desiccant material—such as silica gel—rapidly absorbs moisture from the incoming air, reducing its humidity.

Silica gel is a commonly used desiccant due to its high effectiveness in absorbing water vapor. As the air passes through the breather, the silica gel or similar desiccant material captures and retains moisture particles, effectively dehydrating the air before it enters the storage system or tank.

Look To Advanced Filtration For All Your Industrial Filter Needs

Industrial filtration is a complicated business, but it doesn’t have to be. Reach out to Advanced Filtration today using the contact form to the right of this article, or by calling 732-901-6676 today.

We can help you find the products that fit your needs–whether it’s for power generation or for pharmaceutical and biotech manufacturing–as well as offer a free quote. We look forward to hearing from you!