Archives

April 9, 2024

Water quality is vital in any industrial facility, ensuring all systems and processes function efficiently. Investing in a water filtration system is the best way to ensure the water is impurities-free. In this article, learn all about industrial water filtration systems with the experts at Advanced Filtration. Water filtration systems facilitate effective removal of contaminants to purify water. So, what exactly are industrial water filtration systems, and why are they important? Let's find out as we discuss how these systems work. What Are Industrial Water Filtration Systems? Industrial water filtration systems refer to special equipment that cleans industrial water. These systems eliminate potentially harmful substances like pollutants and impurities from water. They make the raw water safe, clean, and suitable for industrial applications. Industrial water filtration systems are available in different configurations, sizes, and shapes. Each one comes with unique features and capabilities. These systems use filters made from materials like activated carbon and multi-layered sand. They cleanse water through: Nanofiltration Reverse Osmosis Coarse Filtration UV light Ceramic Filtration Ultrafiltration These processes can clean water using chemical treatment, physical filtration, or both. The most suitable one depends on the impurities you intend to eliminate. Different industries use water with varying…

February 29, 2024

Advanced Filtration deals with various industries where fluid handling is essential, and the efficient regulation and management of flow rates, pressure, and temperature are paramount. One crucial component that aids in achieving this efficiency are triple duty valves. This small but mighty piece of equipment comes up time and again when discussing industrial filtration solutions for our clients, so in this blog post, we're going delve into what they are and how they work. We'll also look at their different applications across industries, their significance, materials of construction, and other important aspects. What is a Triple Duty Valve? So, first things first: what exactly is it? A triple duty valve is a specialized type of valve designed to perform three primary functions within a single unit: balancing, throttling, and shut-off. These valves are engineered to control flow rates, maintain system stability, and ensure optimal performance across various fluid handling systems. How does a Triple Duty Valve Work? Triple duty valves operate based on their unique design, which integrates components for balancing, throttling, and shut-off functions. They typically consist of a globe-style valve body with an integrated balance piston or plug. This design allows for precise control over flow rates while maintaining system stability…

February 28, 2024

Last month, we published an article called "The Advanced Filtration Guide to Heat Exchangers," where we discuss all the ins and outs of heat exchange in industrial applications. Today, we're going to discuss the complementary side of that process, which is all about evaporative coolers and condensers. We here at Advanced Filtration deal with so many types of industrial filtration products and applications, and heating, cooling, and temperature control in general is a big part of that. The topic is big and complicated, so please do not hesitate to give us a call at 732-901-6676 or use the contact form on this page for a free consultation. We love answering questions! What Are Evaporative Coolers and Condensers? An evaporative cooler and a condenser are two distinct components used in different systems, often in the context of cooling processes, but they serve different purposes. Evaporative Cooler An evaporative cooler, also known as a swamp cooler, is a device that cools air through the evaporation of water. It operates on the principle that when water evaporates, it absorbs heat from the surrounding air, thereby cooling it. Evaporative coolers are commonly used in dry climates as they work best in areas with low humidity.…

December 27, 2023

Here at Advanced Filtration, we work with a diverse array of industrial filter product, from mist eliminators to Y-strainers to HVAC media filters, and everything in between. You'll find all kinds of literature in our blog about all of these lines we carry, and today we're going to discuss a specific topic: heat exchangers. What Is a Heat Exchanger? A heat exchanger is a device designed to efficiently transfer heat from one medium to another without them coming into direct contact. It's used in various applications where the heat from one fluid (liquid or gas) needs to be transferred to another fluid without mixing them. Many of Advanced Filtration's clients require exact-specified materials for their heat exchanger needs. Heat exchangers are found in everyday appliances, including air conditioners, refrigerators, and car engines. But they are also used in industrial processes such as power generation, chemical processing, and HVAC systems. They come in different types, such as shell and tube, plate, and finned tube exchangers, each suited for specific purposes depending on a variety of factors, including: The required heat transfer efficiency; Space available for the product; The nature of the fluids involved. How Heat Exchangers Work As mentioned above, a heat exchanger works…

December 19, 2023

We here at Advanced Filtration provide industrial filter solutions for all manner of industry, from manufacturing to pharmaceuticals to biotech, and everything in between. One common application we encounter is lube oil filtration, and if this is important in the day-to-day operations of your company, then read on. Why Are Lubricant Oils So Important? Lubricant oils are primarily used for reducing friction and minimizing wear between moving components in machinery and industrial equipment. Their key purposes include: Friction Reduction: Lubricant oils create a thin film between moving parts, reducing the friction generated during their interaction. This helps in smoother operation and prevents excessive wear. Wear Protection: By forming a protective layer, lubricants minimize the wear and tear on surfaces, such as gears, bearings, and other moving components. This contributes to the overall longevity of the machinery. Heat Control: Lubricating oils assist in managing heat generated due to friction. By reducing friction, they help prevent overheating of components, which is crucial for the efficient and safe operation of machinery. Corrosion Prevention: Lubricants act as a barrier against moisture and corrosive elements, protecting metal surfaces from rust and corrosion. Sealing and Cooling: In some applications, lubricant oils are used for sealing purposes,…

November 22, 2023

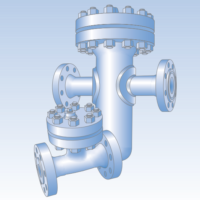

Here at Advanced Filtration, we constantly work with complex mechanical components that play an integral role in managing and maintaining processes. One such component that holds significant importance is fabricated strainers. In this article, the industrial filtration experts at Advanced Filtration in New Jersey are going to look at fabricated strainers, and how they are used in industry to great effect. The Purpose of Fabricated Strainers Fabricated strainers are specially-designed components used to remove solid particles from a flowing medium—typically a liquid or gas. These versatile devices serve as gatekeepers to protect sensitive equipment from potential damage caused by debris or even unwanted chemical reactions triggered by foreign particles. The fabrication process involves creating a custom-made design specific to the application at hand, which provides better control over cost, efficiency, and overall product quality. Advanced manufacturing processes are employed in their construction, ensuring optimal performance under heavy workloads. Notably, they offer better filtration as compared to casted strainer alternatives due to their finer mesh size capability—an advantage that shouldn’t be overlooked when working with high precision applications. Importance of Using Fabricated Strainers in Different Industries Choosing between different types of industrial strainers can feel like navigating through uncharted waters. The…

Advanced Filtration ships throughout the world and offers on site support and service to the New York and Philadelphia metro areas including all of New Jersey, eastern Pennsylvania, southwestern Connecticut and southern New York State.

Advanced Filtration ships throughout the world and offers on site support and service to the New York and Philadelphia metro areas including all of New Jersey, eastern Pennsylvania, southwestern Connecticut and southern New York State.