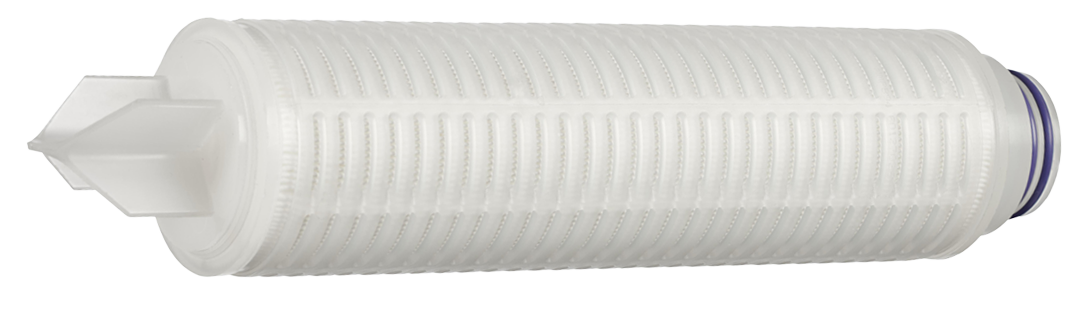

Here at Advanced Filtration, we look at all aspects of the filter industry so that we can provide the best products and services to our customers. In this article, we’re going to take a look at one very specific aspect of our trade: filter cloth.

For industrial filtration applications to succeed, you must use the right filter cloth. This means you must select the suitable filter media carefully to get the best filter cloth that matches the kind of machine it’s to work under.

Remember, there are different types of filter cloths for various applications, which depend on the service life or compatibility. But what should you look for in a filter cloth when choosing the best fit for industrial filtration?

Understanding Different Types of Filter Cloths

Different types of filter cloth range from 1 micron to 1500 microns. Having the right filter cloth enables you to get drier filter cakes with a longer service life. Such helps better the industrial filter press efficiency and lower the maintenance costs. The right type of filter cloth to use depends on its application. For example, filter cloth for food processing differs from that for pharmaceuticals or automotive.

The types of filter clothes include:

Polypropylene Filter Cloth

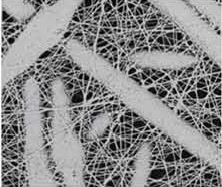

This filter cloth has good acidic and alkali resistance, better conductivity, and wear resistance. Moreover, polypropylene fiber has high strength and is lightweight, which makes it a popular choice for industrial solid-liquid filtration.

This filter cloth has good acidic and alkali resistance, better conductivity, and wear resistance. Moreover, polypropylene fiber has high strength and is lightweight, which makes it a popular choice for industrial solid-liquid filtration.

However, it has poor corrosion resistance and can be used for chemical, manufacturing, ceramic, and smelting operations. But it’s a preferred choice for dye production because of its low moisture absorption capabilities.

Some different polypropylene filter cloths are:

- Polypropylene “mono/multi” filter cloth

- Polypropylene “mono/mono” filter cloth

- Polypropylene “multi/multi” filter cloth

Polyester Filter Cloth

Another type of filter cloth you can opt for is polyester filter cloth. Polyester filter cloth can withstand high temperatures and is an excellent wear-resistant fabric. It’s cost-effective, making it a preferred filter cloth on the market. Additionally, it has good corrosion resistance and recovery. But it’s prone to air permeability and peeling.

You can use this filter cloth to make hotel sheets, tents, filter bags, and army uniforms. It’s also ideal for metallurgical, food, or pharmaceutical applications.

Nylon Filter Cloth

You can also use the nylon filter cloth with high wear resistance. It also has suitable alkali and acidic resistance. But it’s prone to change color, its light and weaker making it not the best for long hours of exposure to the sun.

Nylon filter cloth best suits rubber, food, metallurgy, and ceramic applications at low temperatures. It helps with rough dust and wet solids and is the most popular filter cloth on the market.

Vinylon Filter Cloth

Vinylon filter cloth is not stronger than polyester and has poor elasticity. Furthermore, it has poor shape retention but good wear resistance. It’s also stronger than cotton, can mix with rubber well, and is resistant to strong alkalis.

Vinylon filter cloth also has better hygroscopicity despite not being capable of withstanding low temperatures and shrinking when the temperature hits 100 degrees Celcius. It’s a good choice for the rubber industry or any factory.

Why You Should Pick Specific Types of Filter Cloth

You should use specific filter cloths for different applications because each performs differently on given machines. So, if you want to get the desired results, it’s best to choose the right filter cloth material.

When choosing the right filter cloth for your machine, understand that the filters hold and pull the material differently. The fabrics also stretch, hold, and bend at various levels depending on the force applied.

What To Look for When Choosing Filter Cloth for Industrial Filtration

You should consider the following when choosing a suitable filter cloth:

- Cake Release. Before settling for the filter cloth, you should look at how the cake gets released from the replacement filter. This is because a sticky cake and a dry one get released differently. Since each cloth has unique cake release features, you must select one that will rhyme with the type of cake you deal in. For example, a cake that requires a scraper blade requires a stronger filter cloth.

- Size Of Particles. The particle size also matters, as not all can go through the filter cloth. Filter cloth with bigger pores can handle the bigger particles without challenges. On the other hand, one with smaller pores suits smaller particles. So, check on the pore sizes that can allow the cake, air, and liquid to pass through easily.

- Temperature. When selecting the cloth, remember that each can handle given temperature levels. Each has a maximum operating temperature that, when exceeded, affects the industrial filtration efficiency. Check the temperature range the material can handle before use.

- The Overall Load. You should also know the thickness of the cake to help pick the right filter cloth. A heavy cake requires a strong material that can withstand the weight.

- Cleaning Frequency. Also, know the number of times the filter cloth has to be washed during the filtration process. If it requires you to clean after every cycle, opt for an easy-to-clean filter cloth. You can also go for the one you can clean with a spray bar to reduce workload.

The Bottom Line When It Comes To Filter Cloth in Industrial Filtration

Your choice of filter cloth matters as it determines the type of cake, machine, and particle size it’s going to be used for. So before settling for any, know the kind that suits your needs and gives desired outcome depending on the filtration application.

As you can see, industrial filtration is a complicated process and requires a lot of expertise and know-how. That’s why we recommend giving the experts a call: reach out to us at 732-901-6676 or request a free quote here.